‘Afraid of the water’? Life in a city that dumps billions of litres of raw sewage into lakes and rivers

10 billion litres of sewage are dumped into Winnipeg’s lakes and rivers each year. Some...

This investigation is a cross-border collaboration between The Narwhal and Environmental Health News.

Workers at a steel plant on the Canada-U.S. border are being exposed to lethal, cancer-causing chemicals “with the full knowledge of the employer,” Algoma Steel, according to complaints obtained by The Narwhal and Environmental Health News through a freedom of information request.

The complaints appear to show a series of red flags leading up to an incident in which three workers were exposed to dangerous chemicals and rushed to hospital. One worker alleged the company had provided respirators that were inadequate to protect them.

The company, which operates the plant in Sault Ste. Marie, Ont., is also facing charges for two critical injuries (an injury is deemed critical if a worker breaks an arm or leg, for instance). Ontario’s Ministry of Labour is investigating the workplace exposures, but workers and the union allege the company is putting them in danger and the ministry is too relaxed when it comes to enforcement. A current Algoma Steel employee said the company has become “reactive not proactive,” and if workers don’t push for an investigation, near-miss accidents “get swept under the rug.”

Between February 2019 and February 2020, there were 10 critical injuries and five cases of exposure to chemicals including benzene and asbestos, which cause cancer, and hydrogen cyanide, an extremely poisonous chemical used in death row executions. Over that same period, 89 people also reported occupational illnesses and disease.

Evidence of widespread exposures and injuries at Algoma Steel come months after Environmental Health News and The Narwhal reported that the region already suffers from high cancer rates from industrial pollution, and that Algoma Steel has an exemption from Ontario allowing it to emit cancer-causing benzene and benzo-a-pyrene well above provincial limits. In the wake of the investigation, government officials have taken little meaningful action to protect residents who live near the steel plant from ongoing pollution, apart from $4 million in federal funding to decrease the steel plant’s carbon dioxide emissions and $95,000 to remediate the St. Mary’s River, which separates Sault. Ste Marie, Ont., from Sault Ste. Marie, Michigan.

The region may soon welcome a massive ferrochrome plant, which has stoked concerns of even more local pollution and illness. In August, Noront, the company behind the proposed ferrochrome plant, resumed mining exploration in northern Ontario’s

Ring of Fire. Noront CEO Alan Coutts said he expects no delays to the construction of a northern access road to the Ring of Fire, scheduled to begin in 2021, allowing mining to start in 2025. Noront plans to mine chromite and process it in a ferrochrome plant slated for construction in Sault Ste. Marie, Ont., raising the prospect of hundreds of jobs and fears of more cancer. Noront denies the plant will increase cancer risk.

Algoma Steel Inc. is Canada’s second largest steel producer and the largest employer in Sault Ste. Marie, Ont., with about 2,800 people on its payroll. It produces steel for construction and military vehicles, among other uses, with the majority of sales to U.S. customers.

Algoma Steel didn’t respond to specific questions about incidents but sent a general statement saying it is committed to the health and safety of workers: “Safety is the first responsibility of all Algoma employees including management,” spokesperson Brenda Stenta said. “Our commitment to safety equally extends to contractors and visitors to our premises.”

Workers at the Algoma Steel plant are at risk of being exposed to cancer-causing chemicals and say the company isn’t doing enough to protect them. Photo: Christopher Katsarov Luna / The Narwhal

After publishing an investigation on the impact of industrial pollution on residents, we wanted to learn more about the health and safety impacts on workers at Algoma Steel. We obtained a list of complaints to Ontario’s Ministry of Labour from Feb. 1, 2019 to Feb. 28, 2020. The complaints range from non-critical to critical injuries and exposure to toxic chemicals.

The complaints appear to show red flags in the coke-making department leading up to an incident in which three workers were exposed to hydrogen cyanide gas, which interferes with the use of oxygen in the body and can be rapidly fatal, according to the U.S. Centers for Disease Control and Prevention. (The steel-making process requires coking coal, which is heated to more than 1,000 C, about 1,800 F, in ovens until it forms hard, grey rocks, known as coke.)

On May 8, 2019, an employee reported issues in the coke-making department, including air quality issues, lack of control of airborne hazards, a strange smell from water in the building after rainfalls, lack of a heat stress policy program and workers who weren’t trained on a program for coke emissions. In response to the complaint, Ontario’s Ministry of Labour closed its investigation and took no enforcement action.

On Nov. 29, 2019, employees in the construction department reported they were “unduly exposed to benzene and hydrogen cyanide with the full knowledge of the employer.” They reported the exposure happened while they were doing construction on a low-pressure main, and on the coke-making batteries, and also in the by-products department. They said the types of respirators the company provided were inappropriate to protect them from dangerous chemicals and there wasn’t enough ventilation to mitigate the hazards.

Workers in Algoma Steel’s coke-making department have reported several issues, including poor air quality and lack of training. Photo: Christopher Katsarov Luna / The Narwhal

An inspector visited the plant on Dec. 2 and said the company was resolving the issue and the decanter was being taken out of service. The ministry said construction stopped until the leak was repaired and the company made air quality monitoring available. The ministry said workers are required to wear a self-contained breathing apparatus — a mask that provides clean air from an air tank — when draining coke oven gas condensate “but we don’t know what they were provided with on this specific date as the field visit was conducted on an alternate date.” Again, the ministry closed its investigation and took no enforcement action.

Three months later, on Feb. 26, 2020, an employee reported hydrogen cyanide gas leaking from coke oven batteries, caused by “problems with the by-product and the employer’s inability to clean the liquor.”

As we previously reported, on Feb. 26, 2020, workers were clearing coke oven sludge from a pipe when the hose of the vacuum truck burst and exposed workers to hydrogen cyanide. Three workers were rushed to hospital.

The ministry issued two compliance orders to the company in response to the Feb. 26 incidents and wouldn’t answer questions about events on Feb. 26 because its investigation is ongoing.

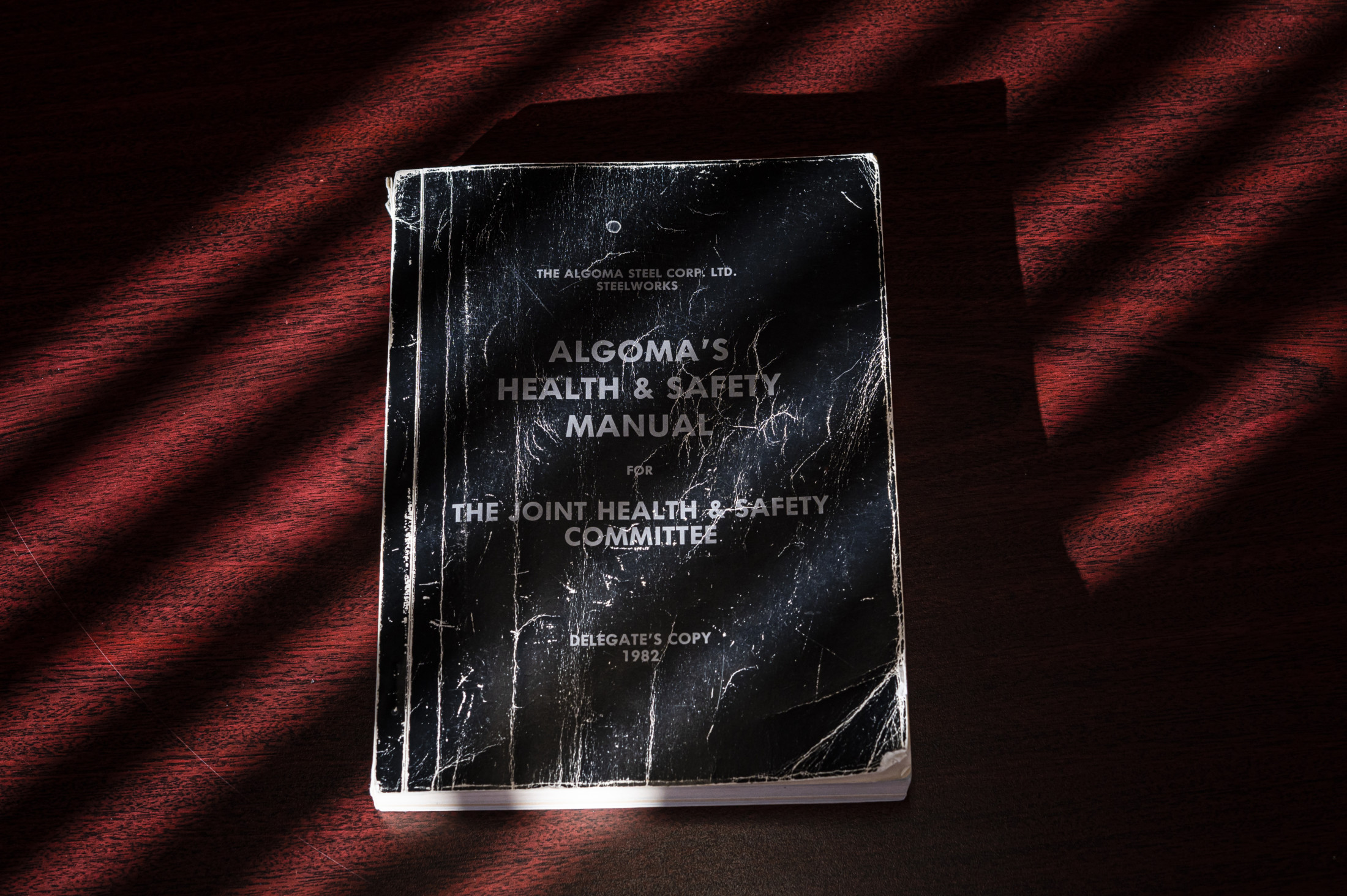

An Algoma Steel health and safety manual from 1982 is shown on the desk of Mike DaPrat, president of the United Steelworkers Union Local 2251, the union that represents most of Algoma’s workers. Photo: Christopher Katsarov Luna / The Narwhal

On Feb. 27, 2019, an employee complained that workers were exposed to cancer-causing asbestos inside the steel plant. Asbestos was falling in two areas of the building, in the basement and on the operating floor.

“The employer has been informed about it a couple times since Dec. 16, 2018, but not looking into it,” the complaint states. An inspector visited on March 5 and issued an order asking the company to update its asbestos record at least once a year and when it becomes aware of new asbestos information.

“The inspector noted that the abatement was scheduled for that week and that the employer has an extensive asbestos management program,” the ministry said.

These dangerous incidents fit into a larger pattern. Since 2001, Algoma steelworkers and their families have reported a total of 1,430 cases of serious workplace illnesses and cancers. Of those cases, 960 claims have been denied and only 320 claims allowed.

With smoke stacks belching fumes 365 days a year next to residents’ homes, the hazards extend outside the walls of the steel plant. Ontario’s Ministry of Environment granted Algoma Steel an exemption known as a “site specific standard” that allows it to emit cancer-causing benzene and benzo-a-pyrene well above provincial limits. A 2019 study found disease clusters of a rare form of leukemia in four industrial border cities, including Sault Ste. Marie, Ont., pointing to pollution as one possible cause.

Algoma Steel has permission from Ontario to emit cancer-causing benzene and benzo-a-pyrene well above provincial limits through what’s known as a “site specific standard.” Photo: Christopher Katsarov Luna / The Narwhal

The ministry is prosecuting Algoma Steel on three charges stemming from two critical injuries on Feb. 4 and Feb. 5, 2019: failing to provide information, instruction or supervision to a worker to protect their health or safety, failing to ensure workplace procedures were carried out and failing to take every reasonable precaution to protect a worker. It’s not clear exactly what happened to cause these critical injuries — the court documents contain few details and the ministry and the company would not comment. On the second charge, court documents allege the company failed to ensure steps were constructed in a manner to prevent a trip hazard.

The court case has been postponed due to COVID-19.

Inspectors with the Ministry of Labour can issue an order, a legal direction to the employer to comply with the law within a certain time period, or if the hazard is imminent, to comply immediately or stop work. Inspectors can also issue a requirement, which is a legal direction saying they have a legal obligation to cooperate with an inspector and provide information. If a company doesn’t comply with orders or requirements, the Ministry of Labour can initiate prosecution under the Occupational Health and Safety Act, and the Ministry of the Attorney General brings those charges forward in court. If convicted, the court can impose fines.

The Sault Ste. Marie International Bridge connects Canada and the U.S. Photo: Christopher Katsarov Luna / The Narwhal

Algoma Steel made more than $2 billion in revenue in 2018, and $1.339 billion in the first six months of 2019. Last year, in response to tariffs, the Canadian and Ontario governments invested $150 million in Algoma Steel. Ontario Minister for Energy, Northern Development and Mines Greg Rickford said a $60-million loan from the province would secure thousands of jobs and pensions, ensure the company remains competitive in a tough market, “and signals Northern Ontario is open for business.” The company took another hit from COVID-19, recently announcing layoffs.

Even as the federal and provincial governments invest in Algoma Steel, the company has not faced any fines or convictions for any of the incidents detailed in the complaints between February 2019 and February 2020. The maximum fine for a corporation charged under Ontario’s Health and Safety Act is $1.5 million per charge, if convicted.

Employers are required under the Occupational Health and Safety Act to protect workers’ safety, and if they don’t, the ministry can issue orders and requirements and take them to court if they don’t comply.

“Our number one priority is the health and safety of workers throughout Ontario,” a ministry spokesperson said. “That’s why from Feb 1, 2019, to Feb 28, 2020, the Ministry of Labour, Training and Skills Development issued 30 orders and four requirements to Algoma Steel.”

United Steelworkers Union Local 2251 president Mike DaPrat was surprised to hear Algoma Steel was facing charges. “The company never bothered to let us know — that’s nice,” he said. DaPrat says a lack of ministry enforcement is the problem; Ontario wants to be “open for business” so the Ministry of Labour is lenient, he explained, citing the death of worker Rocky Scullino in 2008, in which a heavy chunk of iron fell and struck him in the head. Essar Steel Algoma, the previous owner of Algoma Steel, pleaded guilty to failing to ensure overhead guarding was in place to prevent falling materials. The company was fined $375,000.

Mike DaPrat, president of the United Steelworkers Union Local 2251, was surprised to hear Algoma Steel is facing charges. Photo: Christopher Katsarov Luna / The Narwhal

The ministry spokesperson said the ministry doesn’t impose fines — only a court can do that.

Reacting to the fines after Scullino’s death, a current employee who has worked at Algoma Steel for 40 years said, “That’s a case of beer in yours and my terms, it’s nothing.”

Requesting anonymity due to fear of reprisal, he said the company is slow to address small issues that later balloon into bigger problems, and supervisors are hesitant to report near-miss accidents. He said it’s been “mayhem” inside the plant during the pandemic, with the steelworks shutting down and starting back up again. He said while the company is taking the virus seriously, ministry inspectors are doing investigations remotely, online or by phone. Normally workers would do circle checks of equipment, but now they go into an office and check off the paperwork. “They’re done, they’ve got their asses covered now,” he said.

The ministry said it is doing inspections in person and over the phone, as it has always done: “We will spare no expense to ensure health and safety laws are followed. Inspectors are visiting workplaces in-person whenever it is appropriate to do so. Their top priority is ensuring workers are kept safe.”

“Regarding COVID-19, Algoma Steel’s preventative measures and safety protocols have been reviewed by both the Algoma Public Health Unit and the Ontario Ministry of Labour,” Algoma Steel spokesperson Brenda Stenta said. “As of this date, we are pleased to say that Algoma Steel has not had any positive cases and we continue to audit compliance with company protocols daily.”

“Algoma Steel has, in my 40 years, become reactive and not proactive,” the worker said. “Generally we’re disappointed in the complacency of getting stuff addressed. No accountability, that’s exactly what it is, no accountability.”

The worker said the danger to employees stems from a combination of aging infrastructure at the 100-year-old plant, a series of bankruptcies and new owners, cultural factors that lead to injuries and lack of enforcement.

“There are so many risks around every corner,” he said.

“Algoma Steel has, in my 40 years, become reactive and not proactive.”

He recalled an incident in which a 40 pound piece of steel railing fell from 20 feet above, missing another employee’s head by two inches. “That was a very near miss — that could’ve killed him.” But in this case, he alleged the supervisor didn’t want to report the incident because nobody got hurt. He said they had to fight to get it reported. “They tried to bury that. …We went nuts about that.”

He said if employees don’t push for an investigation, near misses “get swept under the rug.” Not many employees push supervisors to report near misses because they could be labeled troublemakers. “There would be repercussions down the road, no doubt. Now the supervisors are all on you, watching your every move.”

“That was just one incident that I was involved with, and that happened all the time,” he said.

He said the ultimate effect is incidents go unreported so the ministry doesn’t investigate, leading to a more dangerous work environment.

“All Algoma employees are required to adhere to all safety procedures and to report every incident, regardless of severity,” Algoma Steel spokesperson Brenda Stenta said. “Our incident reporting system logs every incident, tracks investigations and corrective actions, and is transparent to all employees and union locals.”

There are cultural factors, too. Older workers are willing to put their lives on the line to ensure the plant keeps running, the worker explained. They know the steel plant is the biggest employer in the city, and it has to make money to keep people employed. Recently, he said a coke oven gas condensate line, which is full of benzene and other dangerous chemicals, sprang a leak. His supervisor told him, “get out of there,” and he did, but three other workers wouldn’t leave the building until they finished the task they had to do.

DaPrat said there should be heavy fines for infractions. “If the speed limit is 30 miles an hour [50 km per hour] in this city, if there were no fines, how fast do you think people would be going?”

“Everyone gets up in public and says, safety is the number one priority,” DaPrat said. “Wait a minute, how can it be number one if you’re having all these problems?”

Update January 6, 2021 12:12 p.m. PST: A previous version of this story incorrectly reported the Algoma Steel plant is owned by India’s Essar Group but has been updated to reflect the fact that Algoma Steel Inc. purchased the plant in 2018.

Get the inside scoop on The Narwhal’s environment and climate reporting by signing up for our free newsletter. On a warm September evening nearly 15...

Continue reading

10 billion litres of sewage are dumped into Winnipeg’s lakes and rivers each year. Some...

Court sides with Xatśūll First Nation, temporarily halting Mount Polley mine waste expansion

Break out the champagne: Emma’s storied life and leadership in journalism has earned her the...