The Right Honourable Mary Simon aims to be an Arctic fox

Canada’s first-ever Indigenous governor general doesn’t play favourites among our majestic natural wonders, but she...

This investigation is a cross-border collaboration between The Narwhal and Environmental Health News.

SAULT STE. MARIE, Mich. — A January storm has covered the bungalows here in sparkling snow. Men wearing gloves and hats pulled over their ears steer snow-blowers in and out of driveways, launching powder into the air.

This small city in Michigan’s Upper Peninsula is where the state kisses Ontario. An international bridge connects them across the St. Marys River that flows between Lake Superior and Lake Huron. The river marks the international border between the U.S. and Canada.

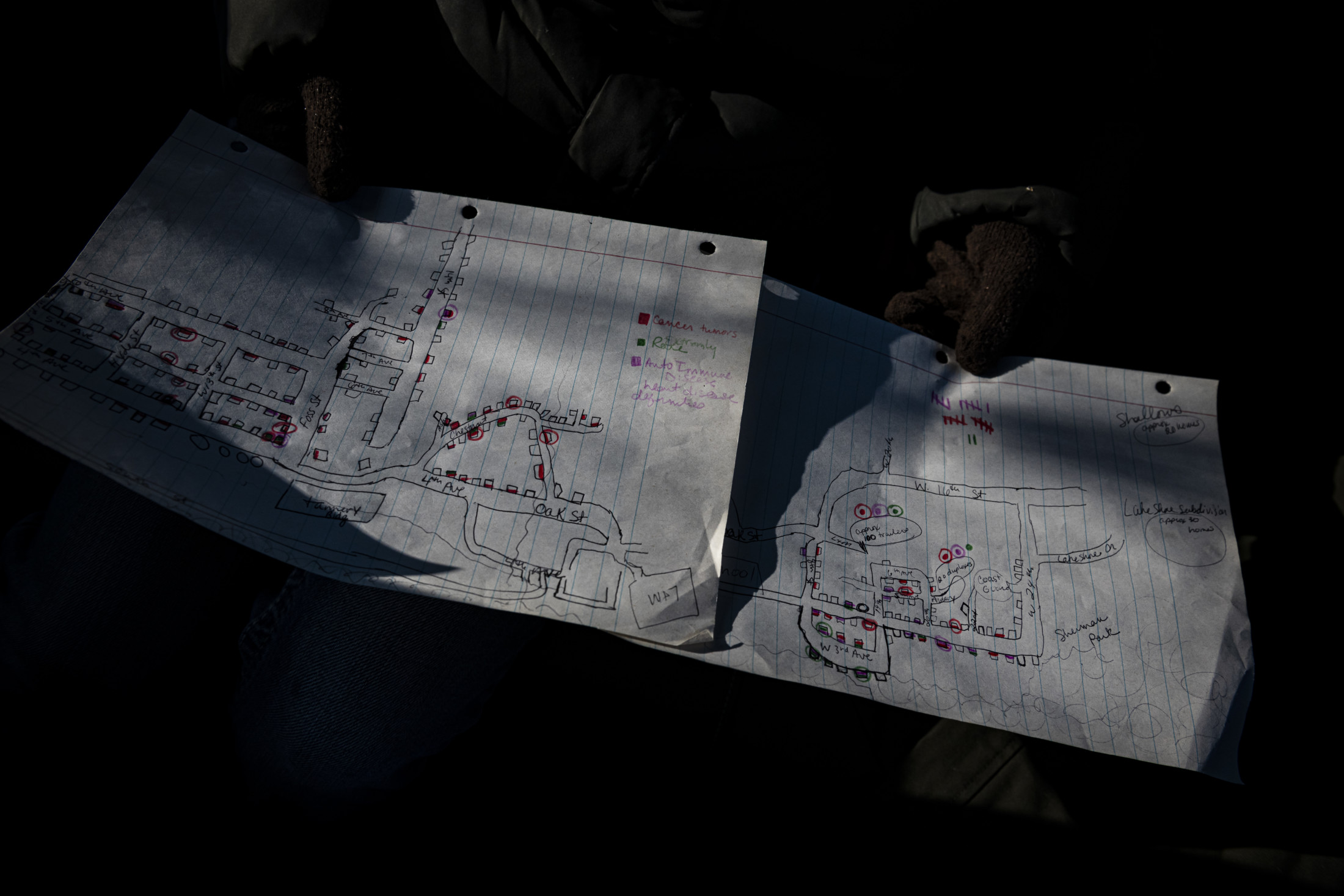

Photographer Christopher Katsarov Luna drives slowly. I turn around in the passenger seat to watch Torry Ruddell in the back, her brown hair falling as she hunches over hand-drawn maps of the area. Many houses are coloured red, indicating that at least one person there has or had cancer.

“Down there my great-grandparents lived,” Ruddell, 44, points.

“It’s got a red circle,” I notice.

“Yeah, my great grandmother, my grandmother, my great aunt and all of my aunts had breast cancer,” she says in a matter-of-fact tone. “My great grandfather had skin cancer.” Her mother also survived uterine and cervical cancer.

We keep driving. “Those people right here, their son had brain cancer,” she says. “He passed away when we were young, still in high school.”

Ruddell holds a homemade map depicting incidences of cancer and other serious or rare illness in households surrounding the Northwestern Leather Company tannery, which dumped toxic chemicals, including chromium-6, into the local environment for half a century in Sault Ste. Marie, Mich. Photo: Christopher Katsarov Luna / The Narwhal

There are other serious illnesses on the map, too, including heart and autoimmune diseases and deformities. But the homes in red are what we focus on.

Many things can increase one’s risk of developing cancer — genetics, smoking, exposure to the sun or radon gas — but there’s no doubt in her mind what’s making people sick.

Ruddell grew up across the street from the Northwestern Leather Company tannery that once stood in this area. From 1900 until it closed in 1958, it dumped toxic chemicals on site. Testing in the late 1970s by Sault Ste. Marie State College and the Michigan Department of Natural Resources found especially high levels of hexavalent chromium in the soil and groundwater.

Hexavalent chromium, or chromium-6, is a chemical made infamous by the film Erin Brockovich

, which tells the true story of how Pacific Gas & Electric contaminated drinking water with chromium-6 in the town of Hinkley, Calif., causing people to develop cancer. The International Agency for Research on Cancer has classified it as carcinogenic to humans, and studies have shown that workers exposed to chromium-6 have a higher instance of lung cancer. Even at low levels, chromium-6 can cause dermatitis and skin ulcers.

A man clears snow after a winter storm, in Sault Ste. Marie, Mich. Photo: Christopher Katsarov Luna / The Narwhal

The Michigan tannery site was remediated in 2007, but data obtained by non-profit organization the Environmental Working Group shows the area still has unhealthy amounts of chromium-6 in its drinking water.

As a kid, Ruddell played on the former tannery site, wading in the mud up to her neck. She picked and ate berries that caused rashes doctors couldn’t explain. There were no signs or fencing warning people to stay away.

Today, a six-foot chain-link fence surrounds the site. On the other side of the fence, there’s a sign covered in snow. I climb over and brush away the snow. It warns against digging wells for drinking water: “Buried tannery waste located on site.”

Ruddell is photographed near the site of a closed tannery where she used to play in mud contaminated with chromium-6 in the community of Sault Ste. Marie, Mich., on Sunday, Jan., 19, 2020. Photo: Christopher Katsarov Luna / The Narwhal

But the tannery isn’t the only source of pollution here. There’s a scent in the Michigan air that’s familiar to people on both sides of the river. It smells like burning tires and rotten eggs.

I ask Ruddell where it’s coming from. “That’d be from across the water there,” she says.

On the other side of the river, a brown steel plant with tall chimneys sticks out against the white landscape. Algoma Steel, the second-largest steel plant in Canada, has stood there since 1902. It belches fumes every day of the year, including Christmas, and has a special exemption from the Ontario Ministry of the Environment, Conservation and Parks allowing it to emit benzene and benzo(a)pyrene, both cancer-causing pollutants, well above provincial health standards.

It’s too late to do anything about the legacy pollution from the tannery or the steel plant, but Ruddell is part of a growing movement of people in the U.S. and Canada organizing against what they perceive as a new threat.

I remember Ruddell’s words when I first called in December: “Them plants are killing us, and they want to put another one in there.”

The Sault Ste. Marie International Bridge photographed from St. Mary’s Island, Ont. Photo: Christopher Katsarov Luna / The Narwhal

For nearly a decade, companies and governments have eyed northern Ontario’s Ring of Fire, a circular mining concession named after the Johnny Cash song, as a promise of economic prosperity. Canadian mining company Noront Resources owns the vast majority of the mining rights in the chromite-rich region, which spans 5,000 square kilometres (2,000 square miles) of the James Bay Lowlands, one of the largest wetlands in the world.

Mining experts have their doubts about how much the Ring of Fire is actually worth, and a lack of roads in the region has hampered development for years. But a recent commitment from the Ontario government to build roads has reinvigorated Noront’s plans to mine chromite and process it in a plant the company hopes to build in Sault Ste. Marie, Ont., nicknamed the Sault (pronounced ‘the Soo’).

Last year Noront entered into a 99-year lease with Algoma Steel to use a brownfield site (a site with a history of pollution) next to the steel plant to build a new ferrochrome production facility — the first of its kind in North America.

The Algoma steel plant after sunset, in Sault Ste. Marie, Ont. Photo: Christopher Katsarov Luna / The Narwhal

Chromite is a mineral used to make stainless steel. First it is converted into ferrochrome through a high-temperature smelting process that can produce chromium-6.

The facility would sit on the banks of the St. Marys River, which connects two massive freshwater lakes and crucial fisheries. It would also be near people’s homes, leading locals to consider selling their houses.

One man told me his family has lived in the area since 1840, and if the plant is built, he’s moving to Panama.

First Nations leaders came forward to say they weren’t consulted. More than 50 doctors signed an open letter opposing the facility and a Facebook group called “No Ferrochrome Plant” sprung up, attracting 4,600 members.

Cancer rates in the Sault are already high — the area has the highest age-standardized rate of cancer in Ontario and the highest provincial rates of lung and prostate cancer. Smoking is more common in the region but doesn’t fully account for the rates. The city’s P6C postal code also has double the national rate of a rare cancer, acute myeloid leukemia. A 2019 study found “disease clusters” of the leukemia in four industrial border cities, including the Sault, suggesting pollution from industry as a possible cause.

The facility will export stainless steel to the American market, but Noront says the plant will bring work predominantly to locals, creating 300 to 500 full-time and 1,500 indirect jobs.

The potential economic boost is welcome news to many locals who remember the years of instability and uncertainty when Algoma Steel, the city’s main employer, went bankrupt and was bought by another company in 2007.

Journalist Hilary Beaumont outside the Algoma Steel plant, a major employer of Sault Ste. Marie residents. Photo: Christopher Katsarov Luna / The Narwhal

The ferrochrome facility will not increase cancer risk in the Sault, Noront president and CEO Alan Coutts insisted in an email. He says the ferrochrome smelting process the company is planning will be nothing like the Erin Brockovich story.

As a by-product of smelting, “the ferrochrome facility may produce trace amounts of chromium-6, which will be captured on the site and destroyed,” Coutts says. Noront wants to use closed-arc furnaces, which the company says generate the smallest amounts of the toxic chemical in the industry.

“If we can’t build a plant that is safe for the employees, the citizens and the environment, we won’t build it,” Coutts says. Yet suspicions are growing around the long-term viability of Noront and the company’s ability to successfully finance its Ring of Fire and ferrochrome plant aspirations — expected to cost in the tens of billions. As The Globe and Mail reported in October, Noront is in “dire financial shape,” holding US$47.8 million in debt and, because of overhyped projections of accessible mineral value in the Ring of Fire, has had trouble attracting investors.

But those abstracted challenges for Noront have done little to alleviate the concern growing on the ground in the Sault.

Before the ferrochrome announcement, many residents were resigned to the fact that they live in an industrial city with high cancer rates. Now, the possibility of another industrial plant has awoken the fight in them.

Liam O’Conner and Tristan Charron set up an ice fishing shanty in Leigh Bay, west of Sault Ste. Marie, Ont., on Jan., 18, 2020. Photo: Christopher Katsarov Luna / The Narwhal

With 2,800 employees, the Algoma Steel plant is the largest employer in the Sault, providing the best paying and most stable jobs in the city. It’s the sole source of income for many families and a point of pride for residents. Prime Minister Justin Trudeau underscored the plant’s national importance when he visited workers during his May 2019 re-election campaign.

Algoma churns out steel used in manufacturing, construction, mining and more. Some of it ends up in military vehicles. “That’s a big-dollar contract for us,” says Andrew, a steelworker, who asked that his real name not be used for fear of losing his job.

Speaking over the phone, Andrew says he is grateful for his work. It provides for his family, and his benefits helped pay for his daughter’s leukemia treatment before she passed.

She was in Grade 8 when she began complaining of pain in her ankle. The doctors in Ottawa did everything they could to keep her alive, Andrew says. She lived just long enough to graduate high school.

“One day she’s graduating Grade 8. The next day she’s fighting for her life.”

Andrew has worked in industrial plants in Sault Ste. Marie and nearby Sudbury and it pains him to wonder if living near the plants contributed to her cancer.

“I just don’t want to see more children dying of cancer for the greed of these corporations,” he says.

To make steel, iron ore is smelted in blast furnaces where high temperatures, created by coking coal, remove impurities and add carbon. In the process, coking coal is heated to more than 1,000 C (about 1,800 F) in ovens until it forms into hard, grey rocks, known as coke.

The smelting process emits coke oven gas and sulphur, Andrew explains. It smells like rotten eggs. “It’s a putrid smell.”

Work at the plant can be dangerous and Andrew says recent events have made him question whether or not the company can keep him and other workers safe.

Machinist Jack Jonson is photographed while at work at a small mill in Sault Ste. Marie, Ont. Photo: Christopher Katsarov Luna / The Narwhal

Machinist Steven Grunewald, who owns a small mill in Sault Ste. Marie, Ont., displays a part he is manufacturing for a machine at Algoma Tubes. Photo: Christopher Katsarov Luna / The Narwhal

Pieces of machine parts made at Grunewald’s small mill. Photo: Christopher Katsarov Luna / The Narwhal

On Feb. 26, a team of Algoma Steel workers were tasked with clearing coke oven sludge from a pipe by flushing it with water, according to Mike Da Prat, president of United Steelworkers Local 2251. Suddenly the hose of the vacuum truck they were using burst, spraying liquid everywhere and exposing workers to hydrogen cyanide. Three workers were rushed to hospital.

“A person got covered in it, and some other people [inhaled] fumes from it,” Da Prat says.

Hydrogen cyanide, a colourless and extremely poisonous gas with a smell of bitter almonds, is produced in coke ovens like those used at Algoma Steel. Hydrogen cyanide is so deadly it’s used as a chemical weapon and for death row executions.

Da Prat says this wasn’t the only incident: in February, two contract workers inhaled hydrogen cyanide while cleaning a tank. They, too, ended up in hospital.

In other recent incidents, blood work revealed workers had low red blood cell counts, a telltale sign of benzene exposure, Da Prat says.

“We’ve got job safe practices and workplace procedure,” Da Prat says. “What happened is, through sloppy management, they’ve been lax, [the practices and procedures] haven’t been adhered to, they haven’t enforced them.” He says workers can’t sue Algoma; they have to file a claim through the Workplace Safety and Insurance Board.

Mike Da Prat, president of the United Steelworkers Local Union 2251, the union that represents most of Algoma’s workers, points to a photograph of the Algoma site in the union’s office in Sault Ste. Marie, Ont. Photo: Christopher Katsarov Luna / The Narwhal

“It’ll be nothing unless you’ve got severe injuries.” The loss of a kidney and part of a bladder was worth $3,300 in a 2008 compensation claim, he says.

Algoma Steel spokesperson Brenda Stenta says the workers who ended up in hospital were all released. In response to the incidents, the company introduced new safety rules requiring workers to wear more personal protective equipment. The company is investigating the events alongside the steelworker unions and the Ontario Ministry of Labour, Training and Skills Development. Stenta says worker safety is the company’s top priority and it will act on the findings of the investigation.

When Andrew heard his co-workers had been exposed to hydrogen cyanide, he felt frustrated and upset. “It’s like we are the guinea pigs for companies’ profits,” he says.

Andrew first awoke to the dangers of industry when he worked at a plant in Sudbury. The air inside was thick with dust and smoke. In the decade since he left Sudbury and moved back to the Sault, at least 10 people he worked with in Sudbury have passed away. The youngest was 39. “Most of it was cancer,” he says.

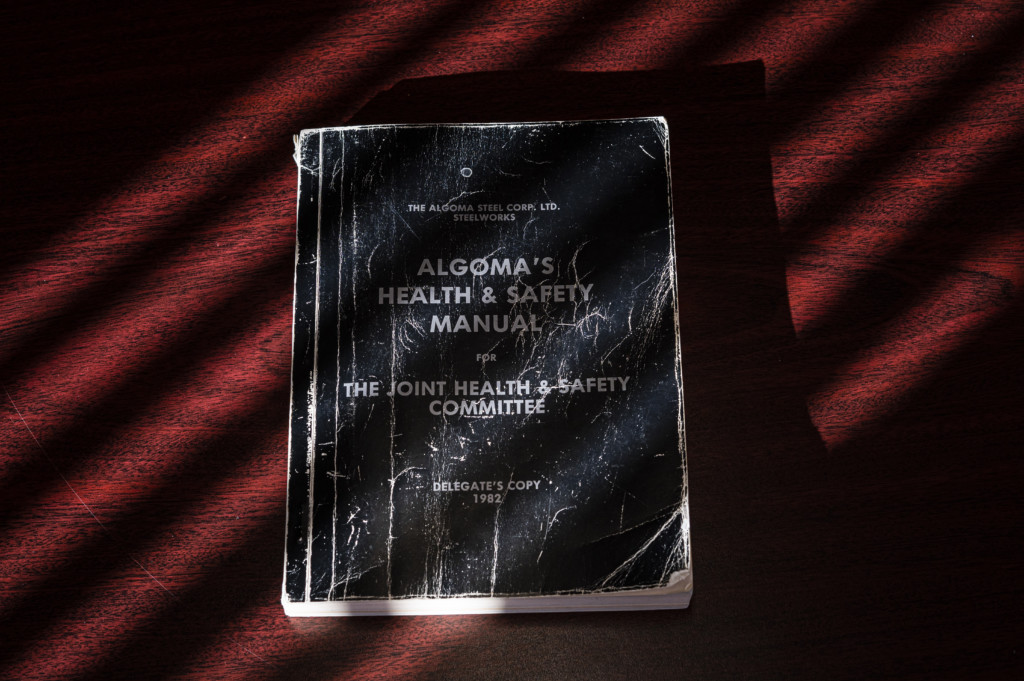

An Algoma Steel Health and Safety Manual from 1982 is photographed on Da Prat’s desk. Photo: Christopher Katsarov Luna / The Narwhal

Da Prat keeps Algoma safety equipment on display in his office. Photo: Christopher Katsarov Luna / The Narwhal

Da Prat says steelworkers at Algoma Steel cannot directly sue the company but can put in a claim for compensation through an insurance board. According to compensation guidelines, “loss of a kidney or a bladder a year ago was $3,300,” he says. Photo: Christopher Katsarov Luna / The Narwhal

The conditions are similar at the Algoma Steel plant, but he doesn’t have much choice. “I know I’m putting my health on the line working there every day to provide for my family, but there’s nothing much out there in the city, ’cause it’s a steel town, eh.”

“Everybody knows the steel plant’s dirty, but it’s what built the city,” he continues. “If the steel plant did shut, this city would become a ghost town.”

Losing his daughter and friends has made Andrew think hard about the ferrochrome facility.

“It’s insane for the city to allow a smelter that will employ 300 people, maybe more, for the profit of the mining industry, where they’re not even looking at the health and safety of the population.”

A study of a ferrochrome plant in Finland found that the plant’s emissions contaminated wild berries with chromium-6 and other heavy metals. Concentrations were higher within three kilometres (about 1.8 miles) of the facility. While no one lives within a 2.5-kilometre radius of the Finland plant, people live across the street from the proposed site of Noront’s facility.

The Algoma Steel plan is visible behind this Sault Ste. Marie, Ont. residential neighbourhood. Photo: Christopher Katsarov Luna / The Narwhal

Some Sault residents were under the impression the facility will be modelled after the Finland plant, but Coutts says that’s not the case. Noront’s chief development officer Stephen Flewelling has said the facility will be the first ferrochrome plant of its kind in the world because of its unique design.

Coutts says the design by Canadian engineering firm Hatch will use direct current electric arc smelting and preheat the ore. According to Noront, the process will recover more chromite so it can end up in the ferrochrome rather than in the leftover waste products known as slag. He says direct current results in better control and capture of chromium-6.

Coutts says the facility will also have “excellent dust control and capture,” which will allow dust from the furnace to be recycled.

Chromium-6 forms in the presence of heat and oxygen, Noront says, so the facility will smelt the ore in a non-oxygenating environment.

But Coutts says the design won’t be finalized until three to five years from now, raising the question of how the company can already be so sure of its safety.

Andrew says unemployed young people desperate for work might see the facility as a benefit to the city.

“It’s creating jobs,” he says. “But at what cost?”

Houses in the Bayview neighbourhood of Sault Ste. Marie, Ont., fall within a few hundred metres of the Algoma Steel plant. Photo: Christopher Katsarov Luna / The Narwhal

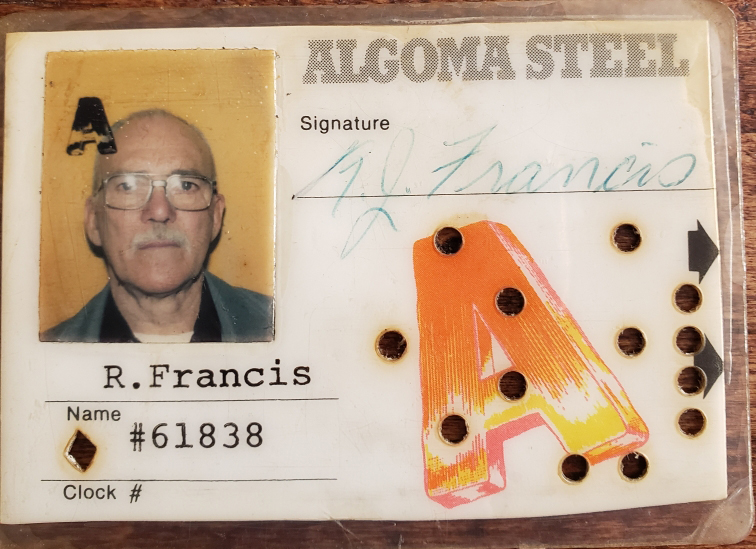

Tammy Francis and her cousin Earl Dunn invite me and photographer Christopher Katsarov Luna to Reggie’s West, a cavernous dive bar frequented by steelworkers in the Sault. We sip cold beer at a table in the back where we won’t be overheard.

Francis, 55, has a small frame and long blond hair that falls in tight waves. She’s standoffish at first but quickly warms up and is unafraid to speak her mind.

She worked at the steel plant for 12 years as a contractor for a fibreglass company. “It’s the dirtiest place I’ve been in my life,” she says. “I’ve been in oil tanks and different things — that steel plant’s no comparison. I refuse to work in there any longer.”

Partly to escape conditions at Algoma Steel, she found work out West. I was lucky to meet her on a trip home as she waits for the next call from Alberta.

Francis has a big family and spends as much time with them as she can. They grew up together in a home in the P6C postal code. But in recent years, her clan has shrunk in numbers. She lost her dad in 2011, followed by her two brothers — all steelworkers, all cancer.

Francis has her dad’s eyes. Reginald Francis was 89 when he died.

Tammy Francis poses for a portrait at Reggie’s West, a bar frequented by steelworkers in Sault Ste. Marie, Ont. Francis lost her father and two brothers — all former steelworkers — to cancer. Francis says she first learned about the proposed ferrochrome plant in a Facebook post. Photo: Christopher Katsarov Luna / The Narwhal

The Algoma Steel identity card of Tammy’s father, Reginald Francis. Photo: Christopher Katsarov Luna / The Narwhal

On Nov. 20, 2011, he went into the hospital with abdominal pain. The doctors found a mass in his colon. He had surgery on Nov. 22, and passed away Dec. 2.

Workplace Safety and Insurance Board records confirm he worked at the steel plant from 1947 to 1989 and succumbed to colon cancer. Tammy says he smoked cigars and a pipe until he quit in his early 40s.

The union provided The Narwhal and Environmental Health News with a list of occupational disease claims that are currently accepted by the insurance board. It details the toxic chemicals that Algoma Steel workers have been exposed to on the job — benzene, coke oven emissions and asbestos are the most common. Chromium-6 is also on the list; the insurance board says workers may develop lung cancer from cumulative exposure to chromium-6 in steel-making.

When Francis filed her dad’s compensation claim in 2011, the insurance board had a policy covering colon cancer and asbestos exposure, acknowledging an association between the two. But after reviewing his case, the adjudicator wrote in a letter to Francis that she found “limited evidence for an association between stomach cancer and colorectal cancers and exposure in asbestos industries.”

The adjudicator acknowledged her dad may have had “some exposure” to asbestos but not enough to warrant compensation.

Earl Dunn drinks a beer at Reggie’s West as his cousin, Tammy Francis, recounts her battle with the Workplace Safety and Insurance Board for compensation after the loss of her father. Photo: Christopher Katsarov Luna / The Narwhal

Algoma Steel is visible from this school playground in the Sault, Ont. Photo: Christopher Katsarov Luna / The Narwhal

“To qualify for benefits, the evidence must show that it is more probable than not that the workplace exposures at Algoma Steel significantly contributed to the development of his colon cancer,” the adjudicator wrote. “I was not able to conclude that Mr. Francis’s colon cancer was causally related to other workplace exposures at Algoma Steel.”

Francis appealed the decision in 2013 and is still waiting for a response. She contacted the union about his case, but she doesn’t believe the union is doing enough to help.

According to the union, as of Aug. 22, 2019, there were a total of 106 colorectal cancer claims like Francis’s dad at Algoma Steel, but only 10 of those claims were accepted.

The numbers show compensation claims for cancer and other diseases are a long shot.

Since 2001, Algoma steelworkers and their families have reported a total of 1,430 cases of serious illnesses and cancers. Of those cases, 960 claims have been denied and only 320 claims allowed.

The majority of the total — 895 claims — were for cancer. Only 164 of these were accepted by the insurance board.

In the six years between 2001 and 2007, families filed claims with the insurance board for 40 Algoma Steel workers who died due to occupational disease, according to the union. The deaths led the union to organize an intake clinic in May 2008 to reach out to the community and identify cases that had gone unreported.

Francis doesn’t care about the money. If her dad’s claim had been allowed, she says it would have meant an acknowledgement that Algoma Steel is polluting the city and causing death.

Locals set up an ice fishing tent in Leigh Bay, west of Sault Ste. Marie, Ont. Emissions from an industrial plant are visible in the background. Photo: Christopher Katsarov Luna / The Narwhal

“If I could have had one more hug, one more kiss — not a million dollars could replace that,” she says. “One more day with my father, or my brothers for that matter. I would give my life to have one more conversation.”

Francis heard about the ferrochrome plant from a Facebook post. “First, of course you think jobs for the city,” she explained. “But as soon as I started looking into it at all, I was 100 per cent against it.”

In September, a group of local doctors published an open letter suggesting they might leave town if the ferrochrome facility is built: “Such facilities are strongly associated with increased cancer rates, mortality and poor health. Our community already suffers from excessively high cancer rates, amongst the highest in Ontario.”

“The site of the Noront facility would be in the heart of our city and on the shores of the Great Lakes waterway with the potential to expose the 70,000 people in our city and the 30 million around the Great Lakes to its toxic by-products,” the letter states.

Rob Suppes, the emergency room doctor who spearheaded the letter, told me people come into the ER with injuries and he’s the first one to tell them they have cancer. It’s one of the hardest parts of his job. Sometimes they’re quiet, sometimes they have questions, sometimes they cry. Suppes, who previously practised in Winnipeg, says never before working in the Sault has he had to diagnose so many people with cancer.

Dr. Rob Suppes was part of a drive to organize medical professionals against the proposed ferrochrome facility. He said since practising medicine in the Sault, he has had to diagnose many people with cancer. Photo: Christopher Katsarov Luna / The Narwhal

When Francis read the doctors’ letter, she immediately worried about the health effects, and her grandkids. “What are we leaving them?”

The idea of a ferrochrome plant has made her reflect more on the industry that’s already here.

“The air we breathe in this city is unreal,” she says. “The smell of eggs at times, the cloud over [the Sault] on a sunny day is unreal. Honest to God … I don’t know how they’re getting away with this.”

Luna and I are up before dawn on a frigid Sunday morning to meet Selva Rasaiah, a former auditor of Algoma Steel who has agreed to show us the plant’s emissions from his favourite vantage point. Rasaiah takes photos of Algoma’s emissions on his own time and writes letters to the Ontario Ministry of Environment when he spots potential violations.

We drive to the base of the towering international bridge on the Canadian side. Rasaiah leads us on foot under the bridge, across train tracks and up a hill through deep snow drifts. At the top of the hill, we see plumes of smoke glowing against the dark sky. The only sounds are a low hum from the steel plant, a truck beeping in the distance and Rasaiah’s voice.

Rasaiah is a talker, especially about environmental regulations. He explains that the clouds we’re seeing are mostly a mix of water vapour and carbon dioxide. Some emissions are from industrial plants owned by other companies: Praxair, an industrial gas company, and Tenaris, steel pipe and tube manufacturer. But the majority of the visible emissions are from the steel plant, Rasaiah says.

Selva Rasaiah describes what can be monitored by observing the visible emissions emanating from the Algoma Steel plant. Rasaiah formerly worked as an emissions auditor inside the plant. Photo: Christopher Katsarov Luna / The Narwhal

The environment ministry says it sets “science-based” air quality standards to protect human health, but recognizes that companies can’t always meet those requirements. So it grants exemptions — called “site specific standards” — on the condition that emissions improve over time.

As of July 1, 2016, the Ontario air standard for benzene was set at an annual average of 0.45 micrograms per cubic metre. But the ministry allowed Algoma to emit an annual average of 5.5 micrograms per cubic metre until the end of 2019. As of Jan. 1, Algoma Steel’s new limit is an annual average of 2.2 micrograms until June 2021. It’s not yet clear if the company will meet that limit.

The ministry says it monitors compliance with the site-specific standard by confirming that Algoma Steel is implementing an action plan designed to reduce emissions.

Algoma is required to observe and record visible emissions from its coke oven batteries and report them on an annual basis. If the company exceeds air standards, it must submit an updated action plan on how it will address the issue.

But Rasaiah questions the reliability of the company’s self-reporting.

In summer 2018, he worked for Pinchin Ltd., auditing Algoma’s emissions. He used something called Method 303 to check for visible emissions of benzene and benzo(a)pyrene.

When workers fill the ovens with coal, it’s called charging. While working for Pinchin, Rasaiah would look for yellowish-orange raw coking gas coming out when the ovens were charging and time it. This gas contains benzene and sulphur. Rasaiah would count the number of leaks, time them and tap the results into a tablet. The numbers are run through a formula to model the total amounts of benzene and benzo(a)pyrene.

The Algoma Steel plant operates under “site specific standards” that allow the facility to release emissions greater than those recommended by the Ontario environment ministry. Photo: Christopher Katsarov Luna / The Narwhal

Although he is no longer an auditor at the plant, Rasaiah continues to visually monitor emissions from the plant and documents them with photos and video. When a reportable event occurs that should trigger a report with the ministry, Rasaiah says he checks the government’s website. There are several recent occasions when emissions events should have been reported to the province, but were not, according to Rasaiah, who says he notifies the ministry every time he documents this happening.

The ministry says it received annual reports from Algoma Steel in 2017 and 2018 showing estimates of its benzene levels were below the site specific standard. Algoma Steel hasn’t handed in its 2019 benzene report yet.

The company also has to meet opacity limits — opacity is the degree to which an emission obstructs light. Algoma must meet a limit of no more than 20 per cent of light blocked over six minutes.

Companies must report discharges and spills to the ministry in a timely manner. Residents can also call the ministry’s Spills Action Centre if they see pollution. When the ministry receives a report, an environmental officer looks into it and decides how to respond.

The ministry says it takes “swift and prompt actions” when companies break the rules and can fine or prosecute them.

In the last 10 years, the Ontario Ministry of the Environment has prosecuted Algoma Steel and its predecessor Essar Steel Algoma on two occasions, leading to convictions and $200,000 in fines. Also in the last decade, the ministry has issued four environmental penalty orders with an additional $27,000 in fines, and 11 provincial officer’s orders requiring improvements to operations.

Rasaiah says air pollution from the steel plant is drifting across the river from Canada to the U.S. Fine particulate matter, also called PM 2.5, is tiny particles in the air so small that when inhaled, they can reach the lungs and lead to all kinds of health issues, including asthma. Long-term exposure can lead to lung cancer and heart disease.

“It’s going to affect your lungs, no different than if you smoke,” he says.

Rasaiah says Algoma Steel’s emissions drift across the St. Marys River into the U.S. Photo: Christopher Katsarov Luna / The Narwhal

An individual walks toward an entry point at Algoma Steel just after sunset. The facility operates day and night, every day of the year. Photo: Christopher Katsarov Luna / The Narwhal

The Inter-Tribal Council of Michigan installed an air quality monitor for PM 2.5 on the U.S. side of the river to monitor fumes from Algoma Steel.

“I feel that the American side is by far getting the worst pollutants, because of the direction of the wind,” says Robin Clark, an ecologist with the council.

It’s tough to prove, though. The group removed the air quality monitor last year because PM 2.5 levels weren’t high enough to be of concern. But Clark believes the monitor was in the wrong location for the wind direction, leading to lower readings.

“We’re all in the same air shed, whether it’s Canada or the U.S. We all own this air that we’re breathing,” she says. “Except now a corporation is going to be taking it further.”

Noront hasn’t approached the ministry about the ferrochrome plant yet, so it’s not clear what specific limits or regulations the facility would have to meet.

Noront says they will run an environmentally responsible facility, but Rasaiah asks: if the ministry gives exemptions to Algoma Steel, will it go easy on the ferrochrome plant too?

Since leaving his position as an emissions auditor at Algoma Steel, Rasaiah regularly documents visible emissions at the facility from this hillside. He reports his findings to the environment ministry. Photo: Christopher Katsarov Luna / The Narwhal

Seven people attend a “petition party” on a Saturday in January in Sault Ste. Marie, Ont. The storm outside may have kept people away, but Rasaiah is here, eager to chat about regulations.

Kathie Brosemer, environmental program manager for the Sault Tribe of Chippewa Indians, is organizing events like this regularly to gather signatures opposing Noront’s facility. She lives in Canada but travels to the U.S. for work.

The Michigan-based Sault Tribe passed a resolution against the facility, stating that the tribe must protect the land, air and water, and that ferrochrome production has a track record of pollution.

A woman drops by with a yellow folder containing four pages of signatures, about 240 names, bringing the total to about 1,000.

Kathie Brosemer poses for a portrait at her home in Sault Ste. Marie, Ont., where she regularly hosts petition parties against Noront’s proposed ferrochrome facility. Photo: Christopher Katsarov Luna / The Narwhal

The Sault Tribe is not the only Indigenous community opposing the ferrochrome plant.

In December, the Batchewana First Nation on the north side of the river came out against the project. In a statement, the chief and council said the decision did not come lightly, and it was their duty to protect the land and waterways. Chief Dean Sayers did not reply to a request for comment.

The chief and council reached the decision based on several key principles, including the Water Declaration of the First Nations in Ontario, which states that First Nations have laws and protocols to ensure clean water for all living things, and the United Nations Declaration on the Rights of Indigenous Peoples (UNDRIP), which says they have the legal right to own, use, develop and control their lands and resources.

Garden River Chief Andy Rickard was elected last September and the ferrochrome facility has been top of his agenda since then. He says many Garden River community members disapprove of the project. Noront has reached out to him to set up a meeting. He says his community will make a decision once the company answers their many questions.

Rickard says his community suffers from high rates of cancer, especially among young people. Too often he sees online fundraisers for cancer treatments.

Cancer survivors and patients gather at a home in Sault Ste. Marie, Ont., on Jan., 19, 2020. Photo: Christopher Katsarov Luna / The Narwhal

The Sault has higher than average cancer rates and many locals fear Norot’s proposed ferrochrome facility will increase the risk of cancer in the region. Photo: Christopher Katsarov Luna / The Narwhal

Residents have complained about a lack of public consultation surrounding Noront’s proposal. Photo: Christopher Katsarov Luna / The Narwhal

The chief of another local community, the Missanabie Cree First Nation, declined to comment for this story.

Noront CEO Alan Coutts says the company had set up meetings with the chiefs and councils of the First Nations. Asked if any First Nations had consented to the project, Coutts says, “We have not asked for consent — it’s too early in the process. Once we have the design and test work complete, we will communicate the results and will allow people to make informed decisions based on factual information.”

Coutts says the company had not yet consulted with anyone on the Michigan side of the river. He says the company was currently scheduling meetings with “various interest groups, including in Michigan.”

“Consultation is a formal process that will begin when the design is finalized and the environmental assessment begins,” he says.

Sault Ste. Marie Mayor Christian Provenzano says the city first began talks with Noront about the facility in November 2016. The company announced it was holding a formal competition, asking cities to compete against each other to be selected as the site for the ferrochrome facility.

On May 10, 2017, Noront presented the idea in the Sault during a luncheon. Provenzano says this was a public event and listing for the meeting notes tickets were available for sale: $28 plus tax for Chamber of Commerce members to attend; $38 plus tax for non-members.

The mayor says in an email that there was “little time” between the date that Noront sent a request for information and the deadline for a proposal. He says he didn’t have enough information to host public consultations.

Usually if a company is selecting a site for a facility, it will do work to identify an appropriate site. In this case, Noront invited cities to do that legwork.

“There was so much interest in attracting the facility that we wanted any city that qualified to have a chance to attract the plant,” Coutts says.

A playground in the Bayview neighbourhood of Sault Ste. Marie, Ont., falls within a few hundred meters of Algoma Steel. Photo: Christopher Katsarov Luna / The Narwhal

According to emails obtained through freedom of information laws, the mayor and city representatives made dinner reservations with the Noront team on Feb. 1, 2018, at Luma, a contemporary seafood restaurant in downtown Toronto, to present their submission.

Coutts says he didn’t pay for dinner. The mayor says the city split the bill with the Sault Ste. Marie Economic Development Corporation.

As the city courted Noront, there were still no public consultations. Then on May 7, 2019, Noront and government officials announced the “good news.” The mayor said after a hard few years the Sault had been selected for the ferrochrome plant and was “open for business.” He said this was only the beginning of the process, and next steps would include environmental assessments and consultation.

Blowback was immediate.

Brosemer, environmental program manager for the Sault Tribe of Chippewa Indians, gathers petitions against the ferrochrome plant. Photo: Christopher Katsarov Luna / The Narwhal

The Clean North office where a petition party was held and organized by Brosemer, on Jan., 18, 2020. Photo: Christopher Katsarov Luna / The Narwhal

Volunteers gather to collect signatures against the ferrochrome plant. Photo: Christopher Katsarov Luna / The Narwhal

The next day, Batchewana First Nation issued a press release saying the announcement “came as a shock” and they had not consented. Chief Dean Sayers says he had met with the Sault Ste. Marie Economic Development Corporation in January 2018, but says “they didn’t go far beyond a simple introduction to the project.” Sayers says the nation sent a letter to the city outlining the steps forward to secure consent, but never heard back.

On its website, the city says its bid to Noront “included letters of support from Batchewana First Nation, Garden River First Nation and Missanabie Cree First Nation.”

Asked about the letter of support, Garden River Chief Andy Rickard says, “I think that’s a false interpretation of that.” He says the previous chief had provided a letter, but it did not grant consent.

“It wasn’t in support of the project, it was just in support of the application going in,” Rickard says.

It’s hard to know exactly what the bid contained because the city won’t make it public. The Narwhal and Environmental Health News filed a freedom of information request asking for it, but the city refused to release it. We have appealed the decision.

Aman Sangar is studying to becoming a welder in Sault Ste. Marie, Ont. Photo: Christopher Katsarov Luna / The Narwhal

Sangar lives in a home with several other students adjacent to the Algoma Steel plant. Photo: Christopher Katsarov Luna / The Narwhal

On Oct. 3, after sustained backlash, the mayor held a news conference. “Everything that has happened to date has happened within the full view of the public,” he said, adding that Noront doesn’t have permission to build the facility yet.

Provenzano says he understands criticism that the city didn’t engage enough with the public before submitting a bid, but adds there will be an environmental assessment, permits and public consultation before the facility can be built.

That’s not entirely accurate.

According to the Ontario Ministry of the Environment, private sector projects including ferrochrome production facilities or smelters “are not automatically subject to Ontario’s Environmental Assessment Act.”

The environment minister could designate it for an environmental assessment, or the proponent can volunteer for one. The ministry says Noront has not yet volunteered for an environmental assessment.

“In three to five years, after the engineering, design, test work and economic analysis is completed, if we decide to progress, we would initiate a governmental assessment,” Coutts tells me in an email.

Once built, industrial plants stand for decades. In the case of the steel plant, as long as a century. They are the scaffolding on which people build their lives. Will the ferrochrome facility ever really be built? It’s not clear. But it has awoken a town to what they have in their backyards.

The snow crunches under our feet as Ruddell and I walk toward the old tannery site on the Michigan side of the river. Two snowmobiles zoom past. “This all should be blocked off, all of it, even the snowmobile trails,” she says.

Algoma Steel, visible from across the St. Marys River, in Michigan. Photo: Christopher Katsarov Luna / The Narwhal

Ruddell said she is frustrated that Americans living near the proposed ferrochrome facility don’t have the right to fight the plant being built, even though they could be negatively affected by emissions. Photo: Christopher Katsarov Luna / The Narwhal

I ask Ruddell how she feels about the ferrochrome plant.

“Some people would look at it as, this area’s already been hit, who cares? But if that happens, there’s no fixing anything then. That’s dangerous. I’ve looked into these things enough that I know what can happen.”

She worries that Americans can’t stop the ferrochrome plant. “Especially being on this side, how much can we really fight against them in Canada?”

“We can do and say whatever to try to stop it, but whose ear do you gotta pull on? I don’t know. Does it worry me? Heck yeah.”

Update April 7, 2020 12:33 p.m. PST: This article was updated to note that in a 2008 worker compensation, a kidney and part of a bladder was valued at $3,300, according to Mike Da Prat, president of United Steelworkers Local 2251. Previously the story indicated the $3,300 figure referred to compensation for a kidney or a bladder last year.

Like what you’re reading? Sign up for The Narwhal’s weekly newsletter.

Get the inside scoop on The Narwhal’s environment and climate reporting by signing up for our free newsletter. A $335 million funding commitment to fund...

Continue reading

Canada’s first-ever Indigenous governor general doesn’t play favourites among our majestic natural wonders, but she...

In Alberta, a massive open-pit coal mine near Jasper National Park is hoping to expand...

A trade war could help remake B.C.’s food system, but will family farmers be left...